Transforming complex polymer testing data into actionable insights

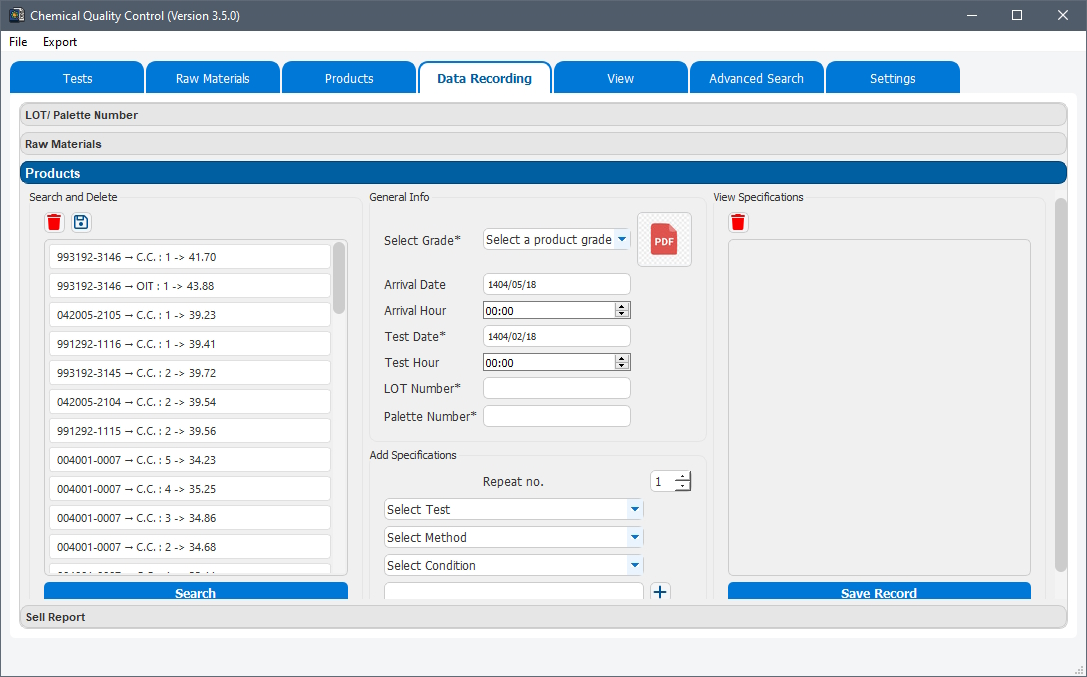

Discover how our LIMS revolutionizes polymer laboratory workflows

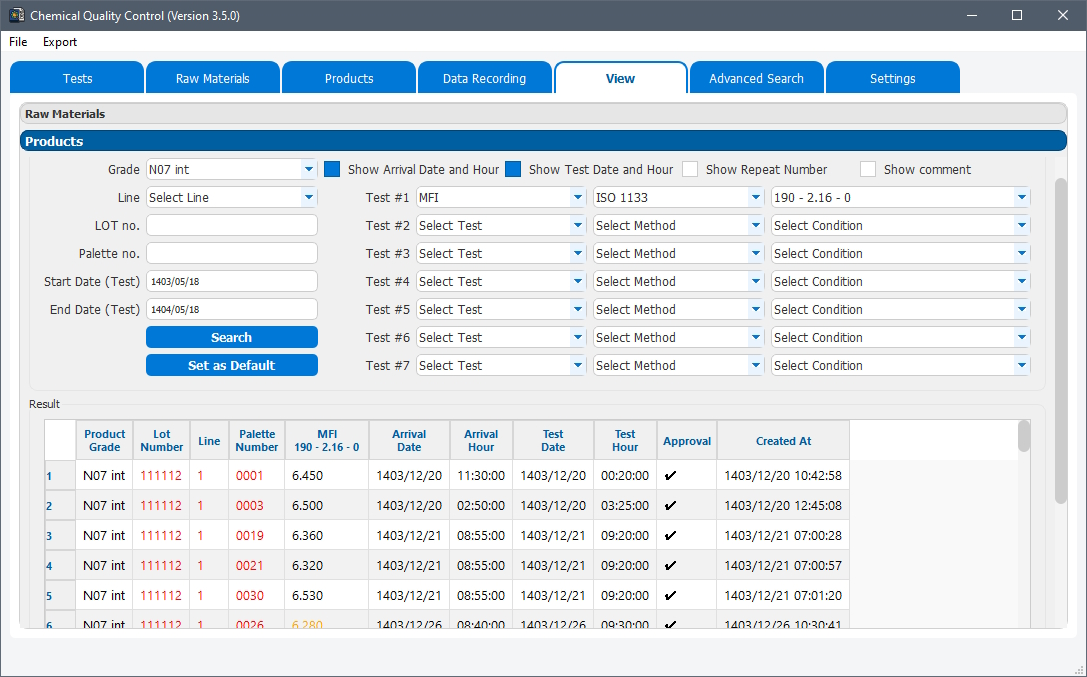

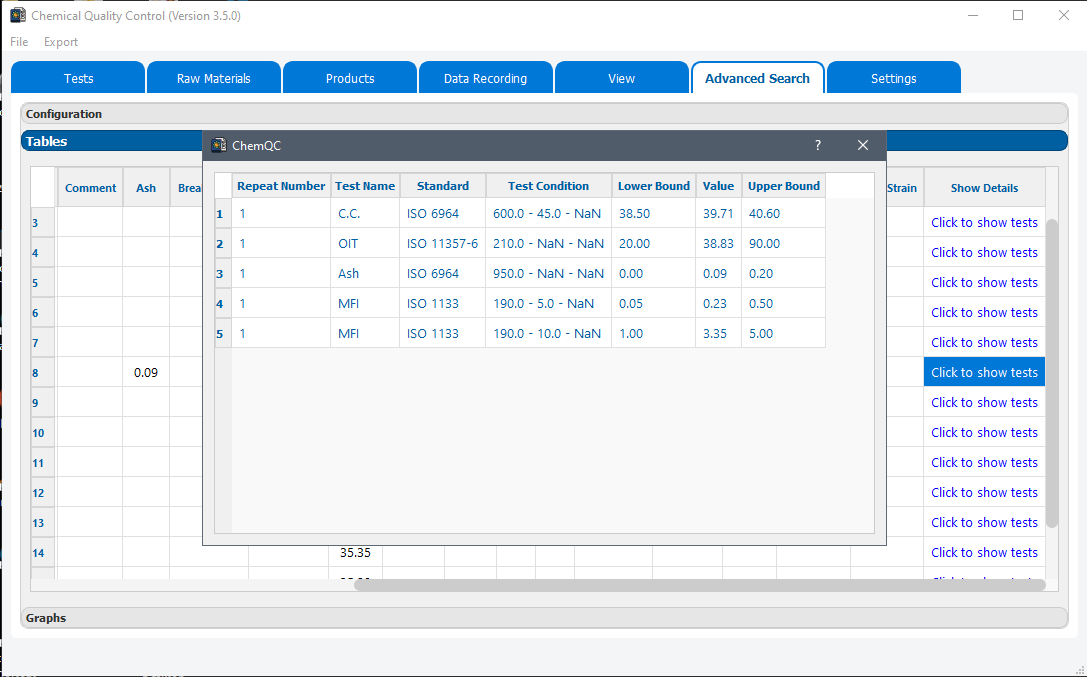

Find any test result within seconds across your entire database

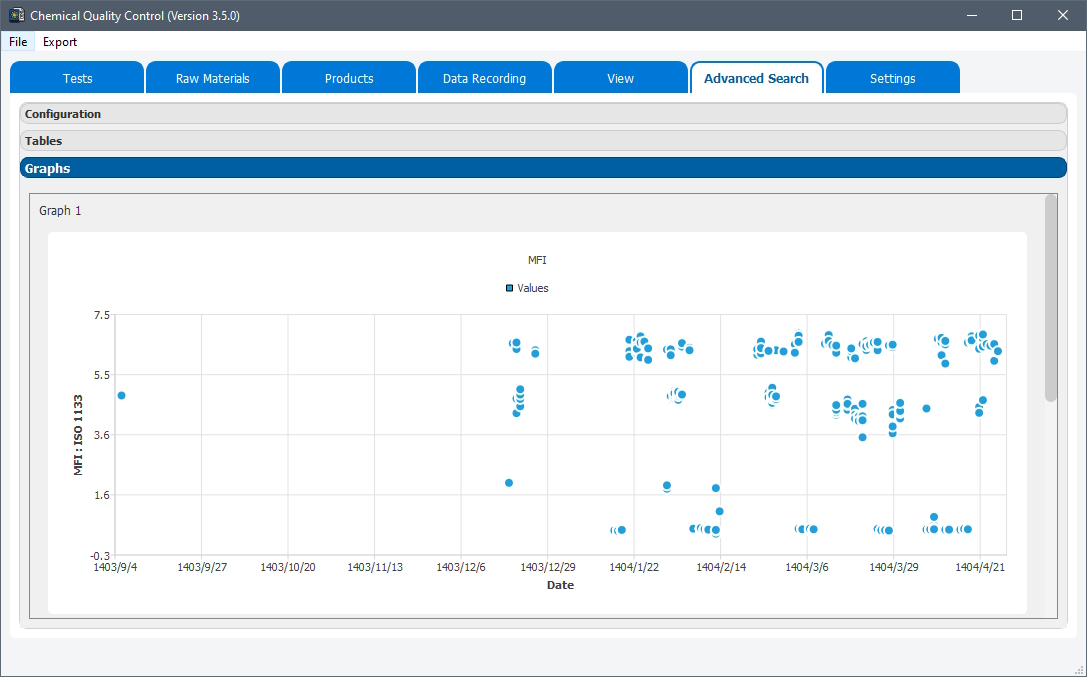

Generate detailed graphs and tabular reports from search results with custom parameters

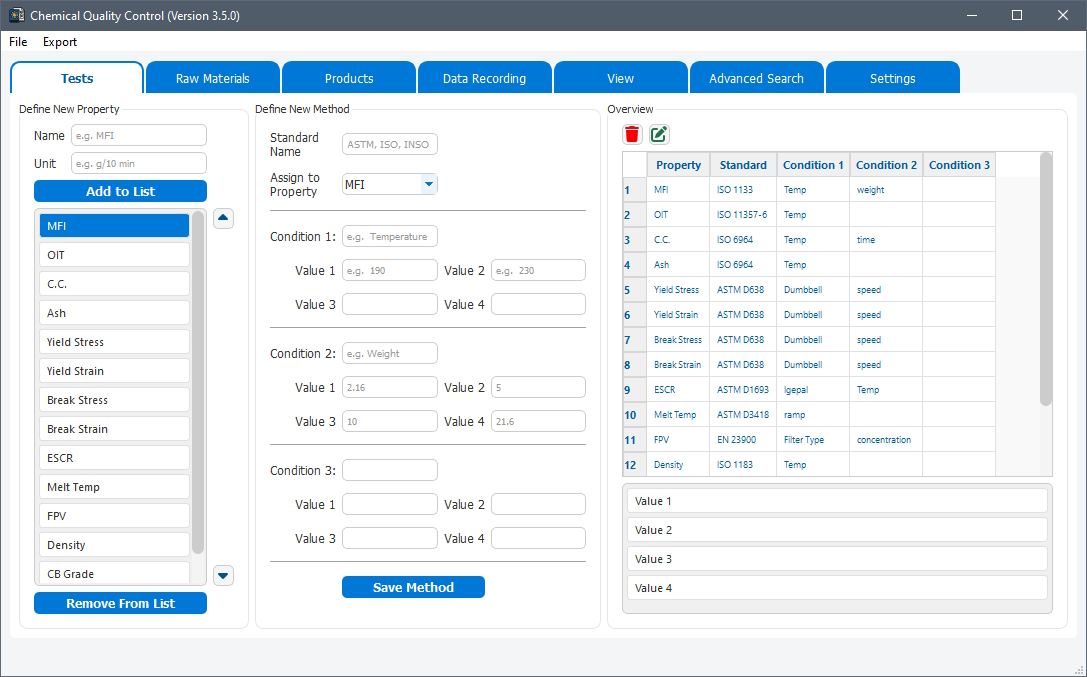

Easily create new testing methods like MFI , ESCR, etc. under different standards (different ISOs, ENs and ASTMs)

Fast storage system for raw materials and finished products.

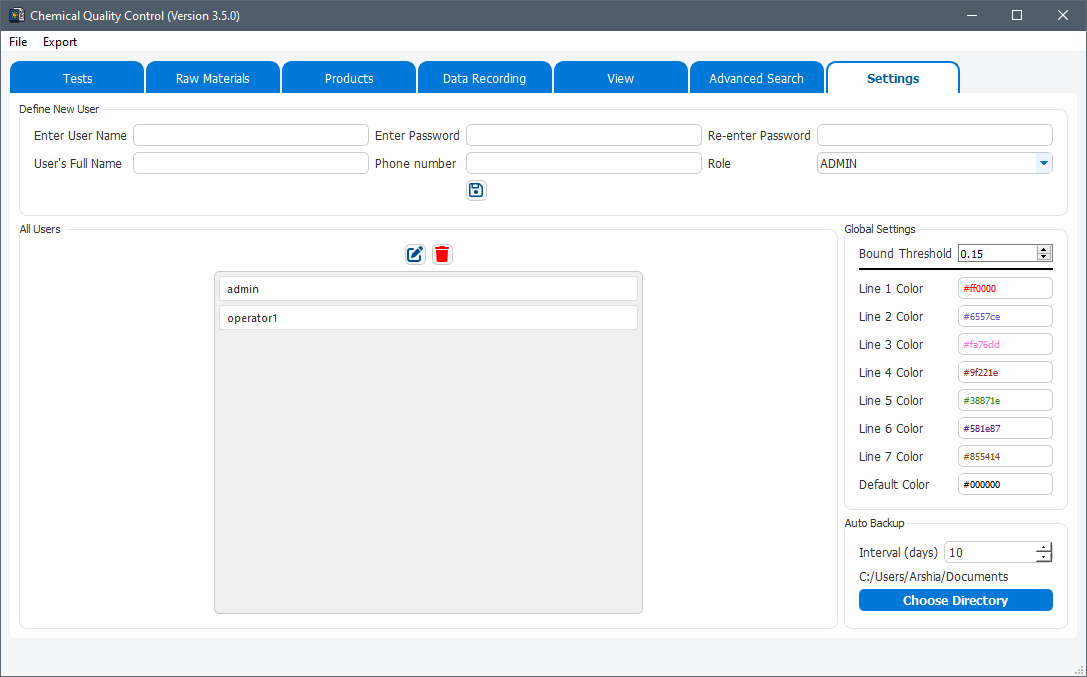

Three user permission levels ensure proper data security management

Export reports as images, spreadsheets, or PDFs instantly with custom formatting